Xanthan Gum for Drilling Fluids — How It Transforms Mud into Mastery

🌍 Introduction

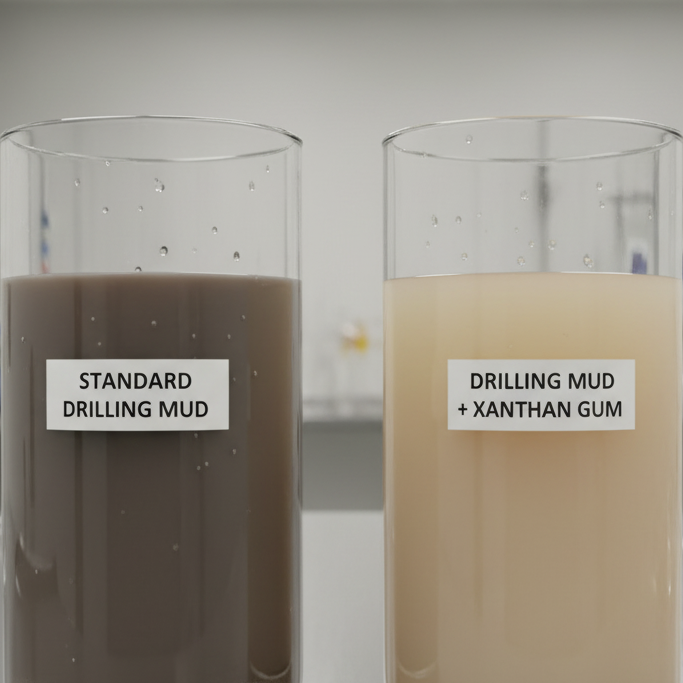

In the world of oil and gas, Xanthan Gum for Drilling Fluids plays a crucial role in ensuring wellbore stability, pressure control, and efficient drilling performance. Drilling fluids — often called mud systems — are the lifeblood of every successful well. They cool the drill bit, transport cuttings, control formation pressure, and stabilize the borehole.

At Coresol, we supply oilfield-grade Xanthan Gum trusted by drilling fluid manufacturers, service providers, and operators for consistent performance — even in high-salinity and high-temperature drilling environments.

⚙️ What Is Xanthan Gum and Why It Matters in Drilling Fluids

Xanthan Gum is a natural rheology modifier produced by fermenting carbohydrates with Xanthomonas campestris. This powerful biopolymer provides high viscosity, excellent suspension, and superior flow control — making it an essential additive in modern drilling fluids.

🧾 Fact Table: Xanthan Gum for Drilling Fluids

| Parameter | Typical Value / Property | Significance in Drilling Fluids |

|---|---|---|

| Chemical Type | Polysaccharide biopolymer | Natural and biodegradable rheology modifier |

| Appearance | Off-white to cream powder | Easy to blend into mud systems |

| Viscosity (1% Soln, 25°C) | 1500–1800 cP | High thickening power at low concentration |

| pH (1% Soln) | 6.0–8.0 | Stable in neutral pH environments |

| Thermal Stability | Up to 90–100°C | Performs under elevated temperature conditions |

| Salt Tolerance | Excellent | Works efficiently in brine and seawater systems |

| Shear Behavior | Shear-thinning | Thickens when static, thins when circulating |

| Environmental Impact | Biodegradable & non-toxic | Sustainable alternative to synthetic polymers |

| Recommended Dosage | 0.2–1.0% w/v | Cost-efficient performance across formulations |

📖 Data Sources: ScienceDirect, ResearchGate, DOE

🧩 How Xanthan Gum Improves Drilling Fluid Performance

Modern oilfield operations demand fluids that are both efficient and environmentally responsible. Xanthan Gum delivers unmatched performance across all key drilling parameters.

🔹 1. Rheology Control

Ensures consistent viscosity under varying shear rates and temperature — resulting in smooth mud circulation and efficient hole cleaning.

📖 Source: AIP Publishing – Rheological Stability Study

🔹 2. Suspension Power

Prevents barite and cuttings from settling, minimizing downtime and stuck pipe incidents.

🔹 3. Fluid Loss Reduction

Improves gel strength, reduces filtration losses, and enhances wellbore stability.

📖 Source: Thai Science Journal – Xanthan Gum Performance

🔹 4. Additive Compatibility

Integrates seamlessly with bentonite, surfactants, and polymers, improving fluid structure and stability.

🔹 5. Lubrication Efficiency

Reduces torque and drag, improving drill speed and energy efficiency in horizontal wells.

🏭 Applications of Xanthan Gum in the Oilfield Industry

| Application | Function | Result |

|---|---|---|

| Drilling Fluids (Mud Systems) | Rheology, suspension, viscosity | Improved hole cleaning, stable muds |

| Completion & Workover Fluids | Suspension, fluid loss control | Better formation protection |

| Cementing Additives | Slurry stability, fluid control | Uniform cement placement |

| Hydraulic Fracturing | Flow modification | Efficient proppant transport |

Learn more about our Oilfield Chemical Solutions

🌎 Why Choose Coresol as Your Xanthan Gum Supplier

At Coresol, reliability begins with sourcing. Our Xanthan Gum for Drilling Fluids meets strict quality standards for viscosity, dispersion, and purity — ensuring consistent performance in both onshore and offshore environments.

✅ Coresol Advantage:

- 🌍 Multi-Origin Sourcing – U.S., India & Southeast Asia

- 🧪 Oilfield-Optimized Grades – For all drilling fluid systems

- 🚢 Port-Proximity Warehousing – Faster delivery, lower costs

- 📜 Regulatory Compliance – SDS, COA, and TDS available

- 💼 Flexible Packaging – 25 kg bags or 500 kg totes

Explore our Supply Chain Capabilities

📈 Performance Benefits of Xanthan Gum for Drilling Fluids

- ✅ Stable viscosity under thermal and saline conditions

- ✅ Reduced Non-Productive Time (NPT)

- ✅ Improved hole cleaning and circulation

- ✅ Consistent mud properties in all drilling environments

📖 Source: Semantic Scholar – Experimental Study of Xanthan Gum in Drilling Mud

🌱 Sustainability and the Future of Biopolymer-Based Drilling Fluids

As oilfield operations shift toward greener practices, biopolymer-based additives like Xanthan Gum are leading innovation. Its renewable, non-toxic, and biodegradable nature supports eco-friendly drilling without compromising performance.

📖 Source: DOE – Sustainable Drilling Fluid Technologies

❓ Frequently Asked Questions (FAQ)

1. What is Xanthan Gum and why is it used in drilling fluids?

Xanthan Gum is a high-molecular-weight biopolymer produced by the fermentation of carbohydrates using Xanthomonas campestris. In drilling fluids, it serves as a rheology modifier that improves viscosity, enhances suspension stability, and maintains fluid consistency under varying shear rates and temperatures — making it essential for efficient oilfield operations.

2. How does Xanthan Gum improve drilling fluid performance?

Xanthan Gum provides shear-thinning behavior, meaning it flows easily while circulating but thickens when static. This property ensures better cuttings suspension, hole cleaning, and pressure control, while also reducing non-productive time (NPT) during drilling.

3. Is Xanthan Gum compatible with other drilling fluid additives?

Yes. Xanthan Gum is highly compatible with common additives like bentonite, barite, polymers, and surfactants. It blends seamlessly in both water-based and brine-based mud systems, enhancing overall stability and performance without affecting pH or system chemistry.

4. Can Xanthan Gum withstand high-temperature and saline environments?

Absolutely. Oilfield-grade Xanthan Gum, such as the one supplied by Coresol, performs consistently in high-salinity and elevated temperature conditions. It retains viscosity even in brine and seawater systems, ensuring stable drilling mud performance in challenging formations.

5. Is Xanthan Gum an environmentally safe drilling fluid additive?

Yes. Xanthan Gum is biodegradable, non-toxic, and derived from natural fermentation processes. It offers an eco-friendly alternative to synthetic polymers, aligning with modern oilfield sustainability goals and environmental regulations.

💡 Partner with Coresol

When it comes to Xanthan Gum for Drilling Fluids, reliability, purity, and performance matter most.

At Coresol, we ensure a seamless supply chain with transparent pricing and technical guidance tailored to your drilling needs.

📩 Contact Us:

Request samples, pricing, or a technical consultation at Coresol Contact Page.

🌐 Visit www.coresolusa.com to explore our complete Oilfield & Industrial Chemical Portfolio.

Leave A Comment